Uses of Silica Sand in Everyday Life

When most of us think of sand, we picture idyllic beaches or children’s play areas. However, this granular material plays a far more critical role in our modern infrastructure and daily conveniences than simply providing a soft surface for sunbathing. Specifically, silica sand—also known as industrial sand—is one of the most widely used commodities on the planet. From the screen on your smartphone to the water flowing from your tap, this versatile resource is likely involved. It is distinct from regular sand due to its high silica content (silicon dioxide, SiO₂), making it chemically inert and incredibly hard. These properties make it indispensable across a vast array of industries.

The backbone of modern construction

The construction industry is arguably the largest consumer of sand, and silica sand is a vital component in this sector. It provides the granular strength and stability required for concrete, mortar, and specialty cements. Because whole grain silica is chemically pure, it doesn't degrade or react when mixed with acidic chemicals or exposed to harsh weather conditions. This durability ensures that the foundations of our homes, office blocks, and bridges remain secure for decades. Contractors often order silica sand bulk bags for large-scale projects, utilising the material for everything from roofing shingles to flooring compounds. Its precise grain size allows for better packing density, which improves the structural integrity of the final building material. Without this specific type of sand, our built environment would look vastly different and likely be far less resilient.

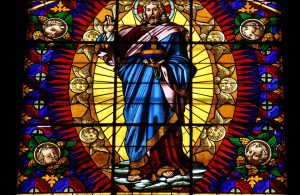

Clear vision through glass manufacturing

Perhaps the most transparent use of this mineral is in the production of glass. Silica sand is the primary ingredient in standard glass formulations, often making up more than 70% of the final product. Whether it is the windows in your house, the windscreen of your car, or the jars in your kitchen cupboard, they all start as grains of silica. The purity of the sand is paramount here; fine silica sand is often required to ensure that the melted glass is free from impurities that could cloud the final product or weaken its structure. For speciality glass, such as the Gorilla Glass used on mobile devices or scientific test tubes, the specifications for the sand are even more rigorous. It must melt at high temperatures and form a rigid, transparent solid that resists thermal shock.

Purifying our water supply

Beyond building and manufacturing, silica sand serves a crucial environmental function in water filtration. Its uniform shape and size make it an efficient filter media for removing contaminants from water. In wastewater treatment plants and swimming pool filters, layers of silica sand trap solids and bacteria, allowing clean water to pass through. The sand bed acts as a physical barrier, catching particles that are too large to navigate the gaps between the grains. This is a natural, chemical-free method of purification that mimics the way aquifers filter groundwater in nature. Because silica is chemically inert, it does not alter the chemical composition of the water, ensuring that the taste and safety of drinking water remain uncompromised during the filtration process.

Enhancing sports and leisure surfaces

In the world of sports and leisure, the ground beneath our feet often relies on engineered sand mixes. Golf courses, football pitches, and synthetic turf all utilise specific grades of sand to ensure proper drainage and root stability. One specialised application is in horse riding arenas. Equestrian silica sand is specifically processed to have a sub-angular grain shape. Unlike round beach sand, which can shift loosely under hoof, these angular grains lock together to provide a firm yet cushioned surface. This provides horses with the necessary grip to perform safely while reducing the impact on their joints. A well-maintained surface is essential for animal welfare, preventing injuries that could occur on slippery or overly deep footing.

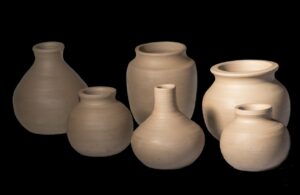

Industrial casting and metal production

Finally, silica sand is a cornerstone of the metal casting industry. In a process known as sand casting, moist sand is packed around a pattern to create a mould. Molten metal—such as iron, steel, or aluminium—is then poured into this cavity. The sand must be able to withstand incredibly high temperatures without melting or fusing with the metal. Silica's high melting point (over 1,700°C) makes it ideal for this purpose. It allows gas to escape during the cooling process, preventing defects in the cast metal parts. From engine blocks in cars to the heavy machinery used in factories, many metal components begin their life shaped by a mould made of humble silica sand. This application highlights just how deeply embedded this material is in the manufacturing chain that supports our industrial economy.